By / Tye Beazer

In the constantly evolving world of HVAC, sheet metal, and piping fabrication, using precision, speed, and coordination are the keys to staying competitive. That’s where BuildCentrix’s Model Spooling capabilities play a huge role, offering a powerful toolset that bridges the gap between BIM coordination and the shop floor.

What is BuildCentrix’s Model Spooling?

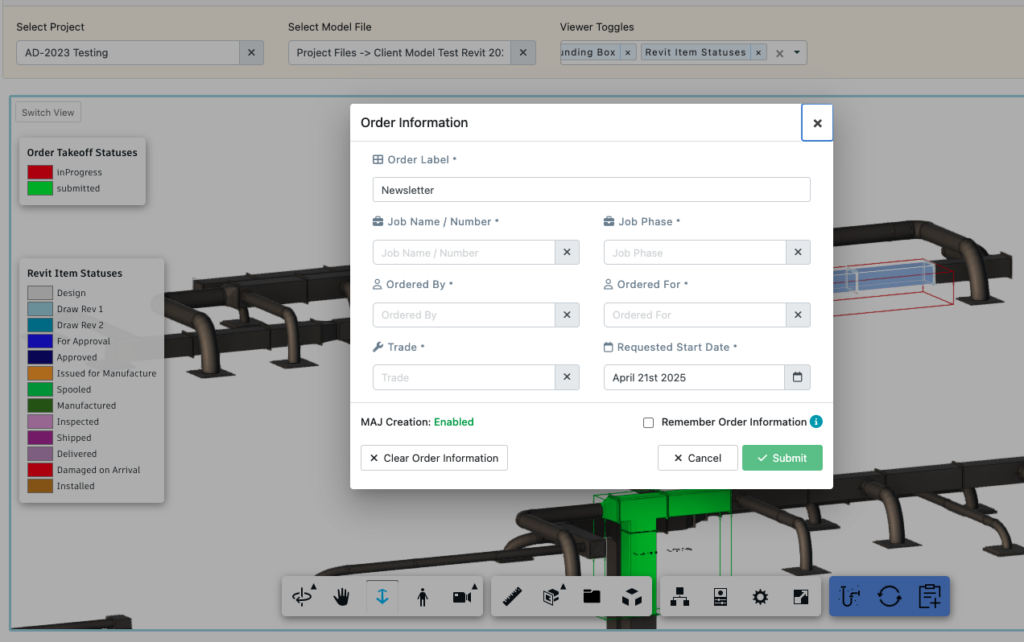

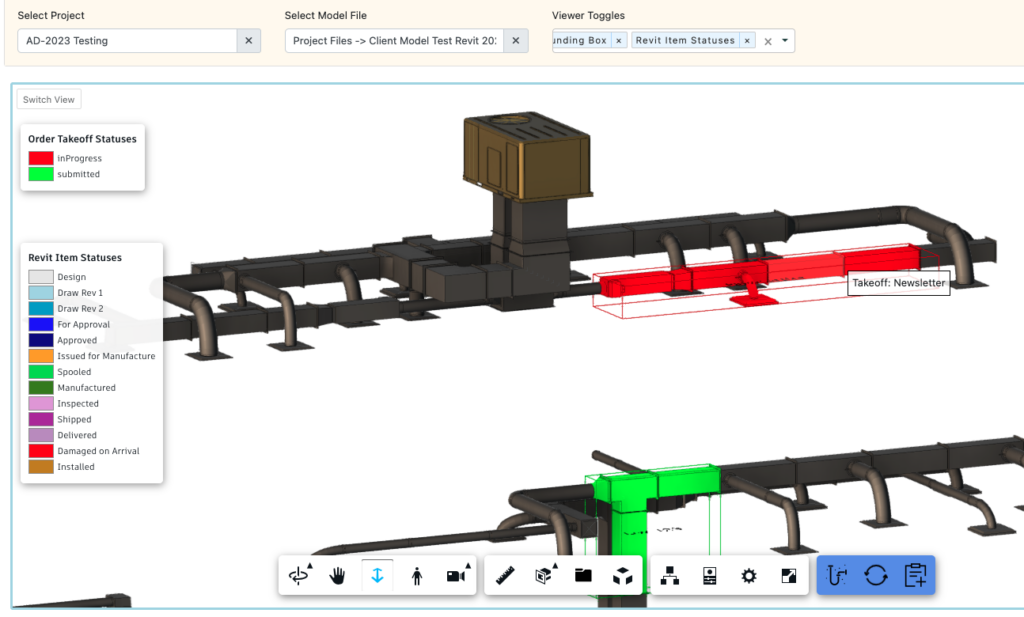

Model Spooling in BuildCentrix is a cloud-based solution that allows fabrication professionals to turn coordinated Revit and CAD models directly into spools, packages, and material orders all in a single, integrated platform. Whether you’re a detailer, project manager, or shop foreman, BCX’s Model Spooling simplifies your work by taking complex 3D model data and transforming it into actionable fabrication documentation and workflows.

BuildCentrix’s spooling system is tightly integrated with Autodesk Revit and other design tools, ensuring seamless compatibility with the models you already use. With just a few clicks, users can spool items from the model, generate labels, assign spools to work orders, and push material lists straight to fabrication, all without leaving the platform.

Key Benefits for HVAC, Sheet Metal, and Piping Professionals

1. Save Time and Reduce Rework

Traditional spooling methods are often manual and disconnected, leading to delays and costly errors. BuildCentrix’s Model Spooling eliminates double-entry and manual data transfer by connecting the model directly to fabrication workflows. This dramatically reduces rework and accelerates project timelines.

“Detailers create spool PDFs within Revit, release those to the site, and the field foreman running the work can mark them up and submit them back,” says James Beveridge, CEO of BuildCentrix. “The resulting .maj file is then released either via email or within a networked folder for download in the shop.”

2. One-Click Material Ordering

A standout feature of BuildCentrix’s Model Spooling is the ability to view and order materials directly from the model. Once a spool is created, material lists are automatically generated based on the components selected. This allows users to send accurate bills of materials to purchasing with a single click, helping to avoid shortages, overordering, and wasted material.

“I think the ‘model status’ writeback is also very compelling, and the real-time status and updates in the model are very beneficial,” Beveridge adds.

3. Integrated with Autodesk Revit

Native integration with Autodesk Revit ensures that spools are always up to date with the latest model revisions. This integration allows users to:

- select model elements directly within Revit or via the BuildCentrix web interface

- create spools and generate fabrication packages instantly

- maintain traceability from model to shop with spool IDs and QR-coded labels

This tight integration streamlines communication between BIM teams and fabrication shops, reducing friction and aligning workflows across departments.

4. Real-Time Shop Floor Visibility

Once spools are created, they’re automatically routed into the BuildCentrix production dashboard where fabrication teams can assign, track, and complete work orders in real time. This means everyone from detailing, procurement, fabrication, and project management has access to the same updated spool data.

“With the shipping and trucking functionality in BCX it’s easy to manage the end-to-end work,” Beveridge says. “Real-time notifications keep the site updated on the status of their material and any changes to the fabrication schedule and delivery.”

5. Improved Collaboration and Accountability

Every spool carries with it a digital paper trail from model to fabrication to installation. This level of visibility enhances collaboration, improves quality control, and creates accountability across every stage of a project. For larger contractors, this can lead to major gains in scalability and consistency across projects and teams.

The Future of Fabrication is Model-Driven

BuildCentrix’s Model Spooling isn’t just a tool; it’s also a smarter way to build. By combining model data with real-time shop floor tools, automation, and cloud-based collaboration, BuildCentrix empowers contractors to work faster, build smarter, and deliver more on time.

For existing BuildCentrix users, Model Spooling enhances the tools you already rely on. For new clients, it’s an entry point into a fully connected fabrication ecosystem that removes silos and replaces outdated processes with a seamless, digital workflow.

Ready to take the next step in fabrication automation?

Explore how Model Spooling can transform your detailing and fabrication workflows by contacting the BuildCentrix team or requesting a personalized demo today.■