Shifting labor force demographics are opening the door for technologies that simplify workflow and offer appeal across generations.

By / Jessica Kirby

The construction industry used to be one of the slowest to implement new technology, but changes in that trend are the biggest news of the decade. The digitization of key tasks in construction is on the rise, thanks to the industry’s renewed focus on sustainability, resource optimization, reducing material and labor costs, and improved quality craftspersonship.

Perhaps the most dramatically affected metric is labor. The United States will need to fill half a million positions in the construction industry over the next five years, and in Canada, 20% of the construction workforce will retire in the next decade. Filling these positions will not be as simple as running a help wanted ad. Success will require a specific demographic that is tech-savvy and productivity-driven, with fingers on the pulse of innovation. The next generation workforce wants creativity and for their work to have meaning. Most of all, they want technology that speeds up or eliminates the more draining elements of their work.

Notice we aren’t pigeon-holing this next generation with age brackets. Anyone can be tech-savvy and appreciate the usefulness of functionality like ordering materials online, rather than by phone or on paper. Younger workers might be more comfortable adopting new technologies, having grown up with devices in their hands, but the experienced generation also appreciates simplicity and productivity. Also, experienced workers have a wealth of legacy knowledge that the industry simply cannot afford to let dissipate as this generation retires.

That makes the solution to the construction industry’s labor problem a hybrid, reciprocal approach to supporting technology integration with legacy knowledge. It means leveraging the best of all generations to facilitate training and best practices, while streamlining digital tools integration. Everybody wins.

BCX has been building out its modules and services using feedback and input from all generations. It addresses multiple pain points with simple tools like 3D rendering for complex fittings, the ability to create online takeoffs, and functionality that offers joint recommendations and automated angle calculations.

“Everything we do is mobile-friendly, a key feature for the next generation of workers,” says James Beveridge, CEO at BuildCentrix. “Experienced tradespersons require the system to be simpler to use and faster to implement, and younger generations want a robust platform that automates tasks like ordering and job costing.”

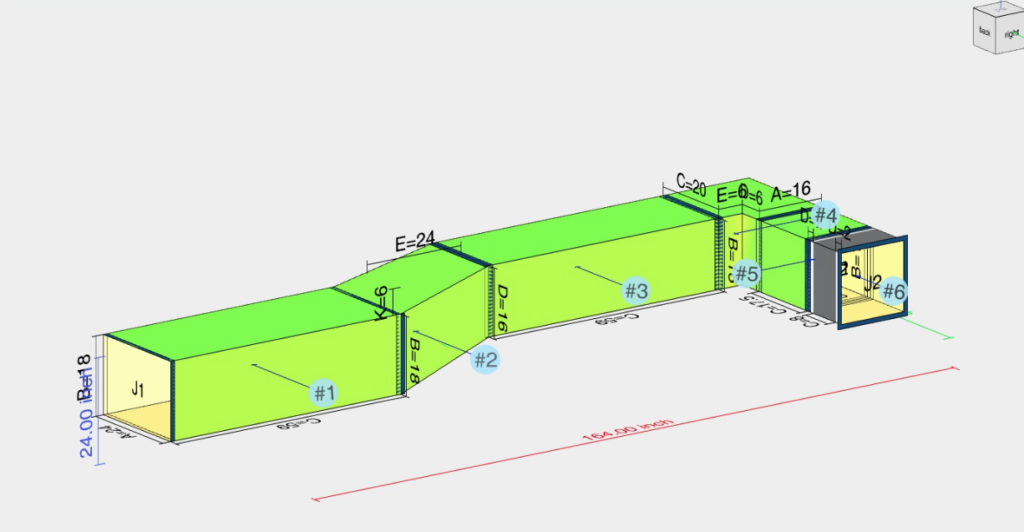

BuildCentrix allows users to create 3D rendering on fittings that change dimensions as they are modified, creating an immediate and gamified visual of what they are creating. Users can also upload blueprints and complete a takeoff right over the digital file, so quantities and costs are fully interactive and visible in real time.

With shop standards built in, BCX removes the guesswork and eliminates user error since the system will not accept fittings that don’t meet the standards. All the checks and mandatory fields ensure that orders must contain all the data points, or the order will not be processed. Access to the timekeeping tool allows mobile tracking of shop production and delivery, so hours and costs don’t have to be entered manually or by phone.

“BCX is focused on building smarter and better,” Beveridge says. “Contractors who implement technology that simplifies tasks and drives productivity will most certainly have the advantage when it comes to recruitment.”

Discover BuildCentrix today with a free demo. ■