We all know time is off the essence and in manufacturing every dollar counts. So when a process fails to meet benchmarks for efficiency and cost-savings, what can a company do? Go lean, go digital, and go to the cloud.

Pure Fabs manufactures sheet metal rectangular ductwork and ancillary items for the HVAC industry throughout the UK. It is part of the Pure Companies Group, which also operates Pure Vent, a contract and installation company, and a plastic ductwork and fume cupboard manufacturing company called Pure Labs.

Pure Fabs employs 16 team members, and within the Pure Companies Group there are over 30 employees and as many as 80 subcontractors working on various projects throughout the UK. Like most of the construction industry world-wide, Pure Fabs used to rely on pen and paper to receive manufacturing orders. But that simplicity came with complicated problems.

“We were receiving information in so many different formats— text, MMS, WhatsApp, email—and some of the site drawings were literally written on the back of a cigarette packet, if we were lucky!” says Pete Connor, director at Pure Fabs.

The information was difficult to read and duct sizes were often misinterpreted, causing setbacks at the company’s expense—its hard to argue with a customer when a number one is mistaken for a seven, Connor says.

“The time implications of having to rush through these items caused other scheduled jobs to be placed further down the manufacture schedule, having a knock on effect, too, with other jobs,” he adds.

The Pure Fabs management team members are huge lean and 5S enthusiasts. Although ventilation ductwork is perceived to be a fairly archaic part of the construction industry, says Connor, the company staff was keen to explore ways to improve their position with customers.

“We wanted to offer them a service that differentiates us from other manufacturers in the UK,” he says. “We were certain there had to be a better way of working that would cut out obvious overlaps and double-inputting of information.”

Like many other manufacturing businesses, as the company had grown, Pure Fabs had simply added new systems to its process, many of which were intended short-term, but became a more permanent “new norm” over time.

“As a team, we carried out a processing mapping exercise,” Connor says. “We found that some jobs had over 85 touch points before delivery.” Something had to change.

The management team started researching off-the-shelf MRP systems and although some had great features, most of them were geared more towards high-volume, low-cost item models, which was not a good fit for Pure Fabs.

“None seemed to tick all of the boxes, but we are fortunate in that our IT guy is rather tenacious when it comes to problem solving,” Connor says. “He spent many an evening scouring the internet for a solution, and this is when he came across BuildCentrix.”

The team read up on BuildCentrix’s ordering, CAM integration, reporting, Production Calendar, and Delivery Calendar services and realized it could be a suitable platform if BuildCentrix was willing to span the distance and time zones, and create a metric measuring option.

“The team at BuildCentrix welcomed out initial approaches,” Connor says. “They already had their eyes on the European market, so maybe the timing of us reaching out was good, or maybe we pushed their decision to press forward with this extension to their portfolio.”

Either way, after a few conference calls between Vancouver and Manchester, both sides agreed it would make sense to push on with a new build of the system, and timelines for implementation and delivery were established. Project teams from both sides were put together, and regular web meetings were scheduled.

“The BuildCentrix team made sure their side of things was as close to being ready as possible, and a week for implementation of the system was agreed upon and carried out, pretty much on plan,” Connor says. “It really helped that the BuildCentix team understood the realities of the industry we work in. The challenges faced in North America are pretty much the same as those faced in Europe, and their experience really showed through during the install process.”

Since implementing BuildCentrix, Pure Fabs has seen an approximate 40 percent time savings on data input in the office. There has been good uptake by the field engineers, who identified the benefits more or less immediately and enjoy the ability to add the price of a job into the contract cost center right away rather than waiting for the price to come back to them.

Another benefit is the way BuildCentrix has standardized Pure Fabs’ process for drawing and inputting trickier double offset items using the pre-installed menus for these pieces. “There are no longer the confused conversations about which view an item has been drawn in, and this has cut down on time, materials, and money in remaking items and transporting to site where a field team has been waiting to finish a job,” Connor says.

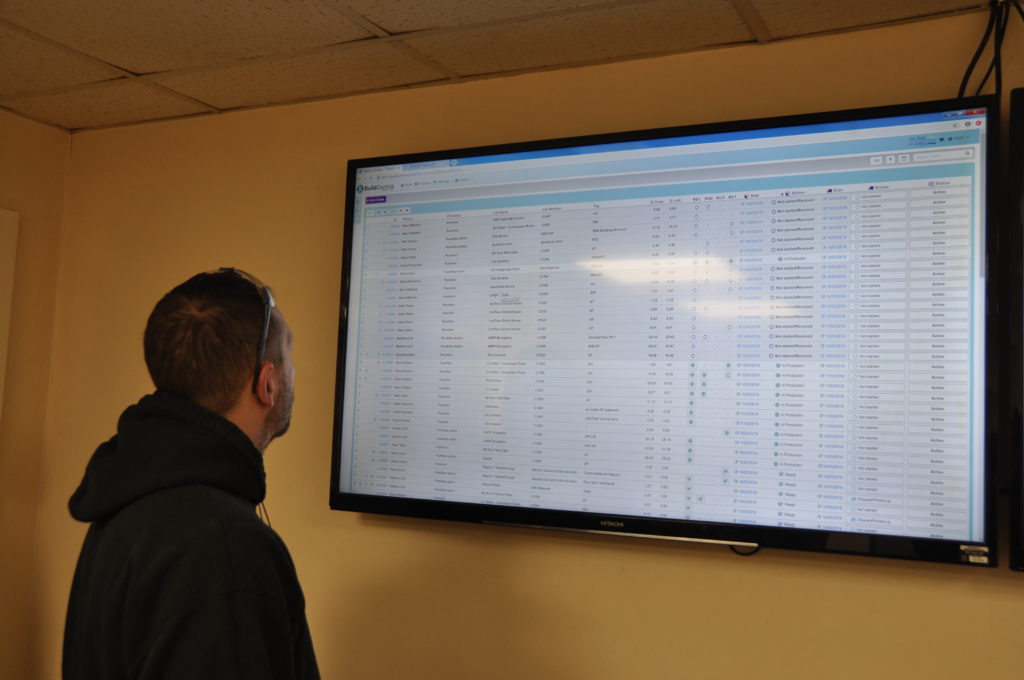

BuildCentrix has helped Pure Fabs centralize its job information— any relevant drawings and timeline information can be attached to and highlighted on the work order. Production and delivery dates can be changed to meet the demands of operating on many sites at the same time. “In construction, what may be required can change in the blink of an eye, and BuildCentrix have incorporated that into its offering,” Connor says.

The implementation was quick and surprisingly easy. Being involved with the comprehensive install meant the office team had the chance to learn the program well, which granted them the confidence to roll it out to the field teams. When both the BuildCentrix platform and the metal (CADDuct) side were fully integrated, rolling out to external customers was a relatively pain-free process, Connor says.

“Every workshop has different ways of manufacturing, and BuildCentrix has to be able to integrate with various machinery and equipment profiles,” Connor says. “With the excellent back up from BuildCentrix, these challenges were kept to a manageable level. Any issues that arose were no different from the usual day-to-day problems faced by every manufacturing facility the world over, and knowing what the end game would produce makes this part of the learning process a more robust and worthwhile experience.”

Currently, Pure Fabs and BuildCentrix are collaborating to improve the way Pure Fabs collects data from the system. “This allows us to produce workshop key performance indicators (KPIs) for the first time, along with adding certain metrics to produce a more detailed overall equipment effectiveness (OEE) for production, along with monitoring waste material closer within individual projects,” Connor says.

As the world expands and timelines shorten the manufacturing sector is looking increasingly for easier ways to do their daily jobs, and BuildCentrix offers solutions. From its easy-to-use Shopping Cart, which mimics some of the top names in online shopping, to its real-time data integration, it is with no doubt the way of the future.

“BuildCentrix places you quite firmly in the realms of Industry 4.0 offering a Cloud-based ordering system,” Connor says. “It puts you ahead of the majority of other suppliers, and you only have to look at the age of the people who will be ordering products in the future to know that the winners will be the ones offering the most relevant systems.”

BuildCentrix as a company does not sit still. Its proactive approach and quick reaction time when necessary puts it ahead of the competition. And, they listen.

“Most importantly, they understand the process, the challenges, and the industry we are working in,” Connor says. “Why would you look to work with a company that hasn’t been born from the particular environment you are in?

“Paper and pen may still have a place in construction, but it will become increasing less so every year that passes—get on board now, or risk being left behind.” ■

By Jessica Kirby